- Home Page

- Company Profile

- Our Products

- Contact Us

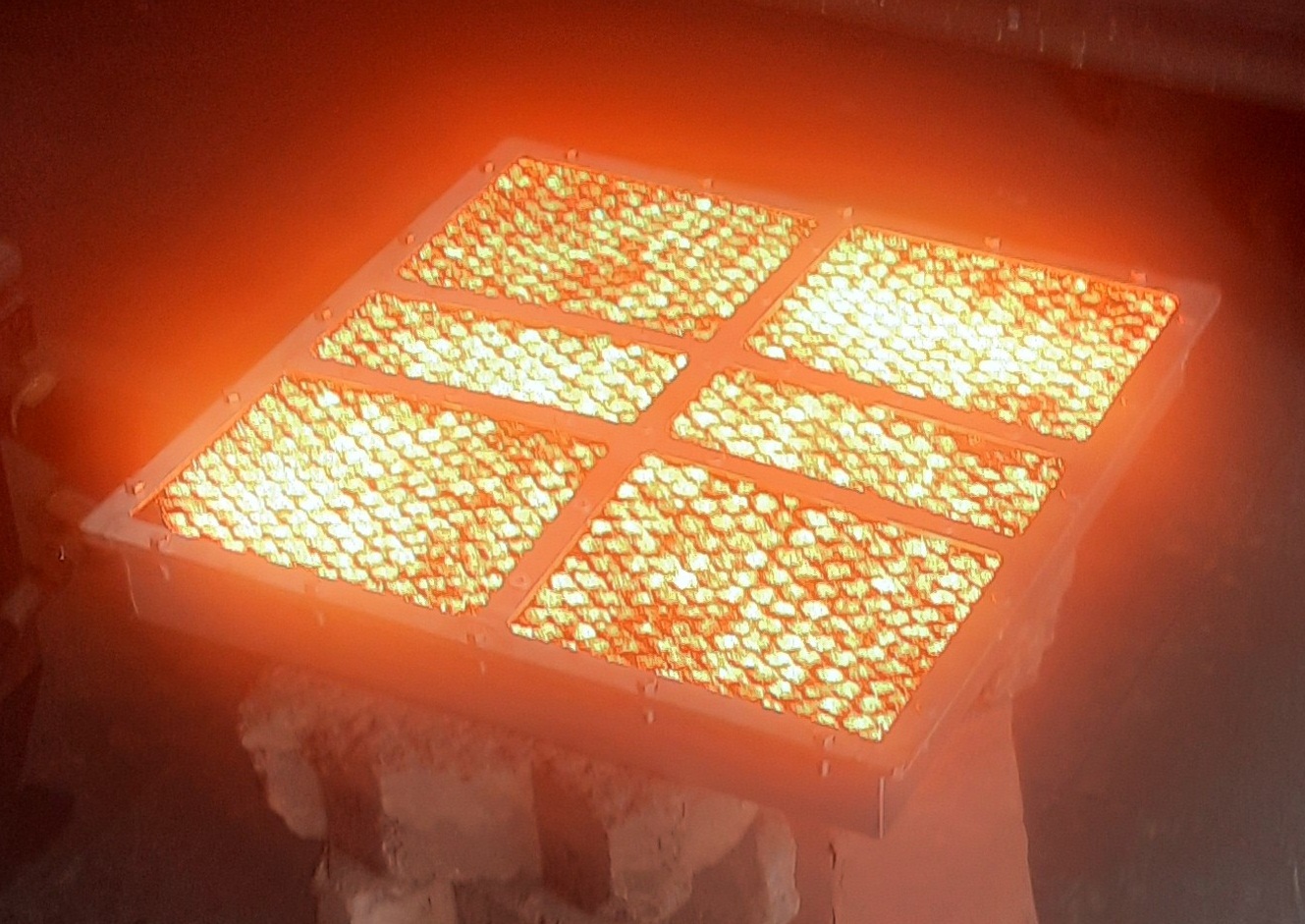

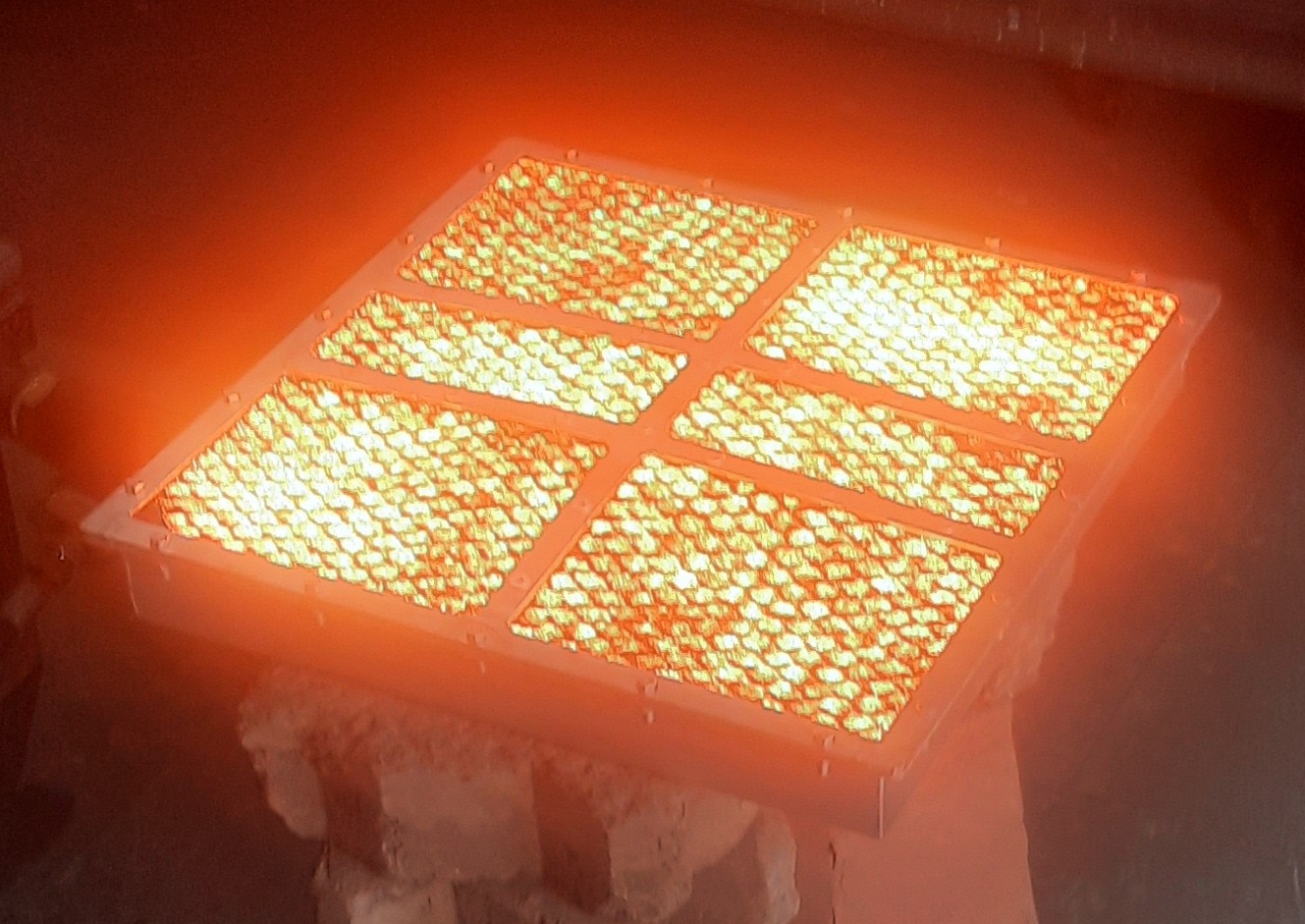

Infrared Gas Burner

6500.00 - 24750.00 INR/Unit

Product Details:

- Usage Food Industry, Paint Industries, Road Repairs, Printing Industries, Room Heating

- Condition New

- Size Standard

- Product Type Gas Burner

- Color Golden

- Material Brass

- Click to View more

X

Infrared Gas Burner Price And Quantity

- 1 Unit

- 6500.00 - 24750.00 INR/Unit

Infrared Gas Burner Product Specifications

- Gas Burner

- Brass

- Standard

- Food Industry, Paint Industries, Road Repairs, Printing Industries, Room Heating

- Golden

- New

Infrared Gas Burner Trade Information

- 2-3 Week

- All India

Product Description

An infrared gas burner is a type of gas burner commonly used in various applications such as cooking, heating, industrial processes, and outdoor grilling. Unlike traditional open-flame burners, infrared burners use infrared radiation to transfer heat directly to the target surface or object without the need for direct contact.

Here's how an infrared gas burner works:

1. Burner Construction: An infrared gas burner consists of a ceramic or metal surface with tiny pores or holes. Behind this surface, there are gas burners that release natural gas or propane.

2. Combustion: The gas released from the burners mixes with air and undergoes combustion, producing a high-temperature flame.

3. Infrared Radiation: The flame heats up the ceramic or metal surface. This surface becomes extremely hot and emits infrared radiation, which is a form of electromagnetic radiation with wavelengths longer than visible light.

4. Heat Transfer: The emitted infrared radiation travels through the air and heats up the objects or surfaces located in front of the burner. This is a more direct and efficient way of transferring heat compared to traditional convection heating, where hot air circulates to heat objects.

Advantages of Infrared Gas Burners:

1. Faster Heating: Infrared burners provide rapid and even heating, reducing the preheating time for cooking or industrial processes.

2. Energy Efficiency: Because infrared burners directly heat the target surface, less heat is lost to the surrounding environment, making them more energy-efficient.

3. Precise Control: Infrared burners can be adjusted to produce specific levels of heat, allowing for precise temperature control.

4. Even Cooking: Infrared burners can eliminate hot spots and cold spots on the cooking surface, resulting in more even cooking.

5. Reduced Flare-ups: In applications like grilling, the direct heat transfer reduces flare-ups caused by dripping grease.

6. Easy Maintenance: Many infrared burners are made from durable materials and are relatively easy to clean and maintain.

FAQ:

Q. What is an infrared gas burner?

Ans: An infrared gas burner is a type of burner that uses infrared radiation to transfer heat directly to objects or surfaces without the need for direct contact. It is commonly used in applications such as cooking, industrial processes, and outdoor grilling.

Q. How does an infrared gas burner work?

Ans: An infrared gas burner emits a high-temperature flame that heats up a ceramic or metal surface. This surface then emits infrared radiation, which heats up the objects or surfaces located in front of the burner. The heat transfer occurs through electromagnetic radiation rather than through the circulation of hot air.

Q. What are the advantages of using infrared gas burners?

Ans: Advantages include faster heating, energy efficiency, precise temperature control, even cooking, reduced flare-ups in grilling, and easy maintenance. Infrared burners can also eliminate hot spots and cold spots, resulting in more consistent cooking or heating.

Q. What are the applications of infrared gas burners?

Ans: Infrared gas burners are used in various applications such as residential kitchens, commercial cooking (restaurants), industrial heating processes (paint drying, plastics molding), and outdoor grilling.

Q. Are there different types of infrared gas burners?

Ans: Yes, there are different types of infrared gas burners, including ceramic plate burners, metal mesh burners, and quartz tube burners. Each type has its own design and characteristics suited for specific applications.

Q. Are infrared burners energy-efficient?

Ans: Yes, infrared burners are generally more energy-efficient compared to traditional burners. They transfer heat directly to the target surface, minimizing heat loss to the surrounding environment.

Q. Can I use infrared burners in my home kitchen?

Ans: Yes, many modern home ovens and stovetops incorporate infrared technology for quicker and more even cooking. However, not all appliances use infrared burners, so it's important to check the specifications.

Q. Do infrared burners produce smoke or emissions?

Ans: Infrared burners produce combustion byproducts like any other gas burner. However, their efficient combustion process often results in fewer emissions and smoke compared to open-flame burners.

Q. Are infrared burners safe to use?

Ans: Infrared burners are generally safe when used according to manufacturer guidelines. Proper ventilation is important to ensure the release of any combustion byproducts. As with any gas-burning appliance, following safety precautions is crucial.

Q. Can I retrofit my existing grill with an infrared burner?

Ans: In many cases, it's possible to retrofit an existing grill with an infrared burner. However, the process might require modifications and adjustments to ensure proper installation and performance.

Q. Do infrared burners require special maintenance?

Ans: Infrared burners are relatively easy to maintain. Regular cleaning of the ceramic or metal surface and checking for clogs or debris in the burner ports will help ensure optimal performance.

Q. Can infrared burners be used for industrial processes?

Ans: Yes, infrared burners are commonly used in industrial processes such as drying, curing, and heating applications where precise and efficient heat transfer is required.

Reliable Infrared Heating Solution

Our infrared gas burner, made from durable brass, stands as a powerful tool for varied industrial applications. With its standard size and golden hue, it combines style and resilience. The advanced infrared technology ensures quick and even heating, optimizing processes in food, paint, printing, and roadwork industries, as well as providing effective room heating. Manufactured in India, it promises quality and long-term performance.

Versatile Industrial Applications

This gas burner is engineered to serve multiple industries, catering to the specific heating requirements of food processing units, paint factories, road repair crews, and print shops. Its robust construction and adaptable design make it an indispensable asset for both large-scale facilities and smaller operations. The burner excels in delivering consistent heat output, supporting diverse tasks with efficiency and safety.

FAQ's of Infrared Gas Burner:

Q: How is the Infrared Gas Burner installed and operated?

A: Installation of the Infrared Gas Burner is straightforward and can be done by connecting it to a compatible gas supply according to manufacturer guidelines. Operation involves igniting the burner and adjusting the flame as necessary to suit specific heating requirements for your application, whether in the food, paint, printing, or road repair industries.Q: What types of industries can benefit from using this gas burner?

A: This burner is suitable for the food industry, paint industries, road repairs, printing industries, and for room heating. Its universal design and reliable brass construction make it a versatile solution for heating and processing tasks in these sectors.Q: When should I use an infrared gas burner instead of a conventional burner?

A: You should choose an infrared gas burner when you need efficient, uniform, and rapid heating. Its technology makes it especially beneficial for applications where precise temperature control and energy efficiency are important, such as in food processing, paint drying, or printing operations.Q: Where is the Infrared Gas Burner manufactured and supplied from?

A: Our Infrared Gas Burner is manufactured, supplied, and traded in India by reputable companies committed to quality and reliability, ensuring local and international availability as required.Q: What is the process for maintaining the Infrared Gas Burner?

A: Regular maintenance includes routine inspection, cleaning the brass components to prevent residue build-up, checking for leaks, and ensuring all connections are secure. Following the manufacturer's maintenance schedule will help prolong the burner's lifespan and maintain optimal performance.Q: How does using this gas burner benefit industrial operations?

A: The burner delivers consistent infrared heat, resulting in faster processing times, energy savings, and reduced downtime. Its durable brass construction also minimizes the need for frequent replacements, thereby lowering long-term operational costs.Q: Which materials and features enhance the burner's utility in industrial environments?

A: Constructed from high-quality brass and finished in golden, the burner offers superior heat resistance, corrosion protection, and longevity. Its standard size and new condition ensure a seamless fit and dependable operation in various industrial setups.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese