- Home Page

- Company Profile

- Our Products

- Contact Us

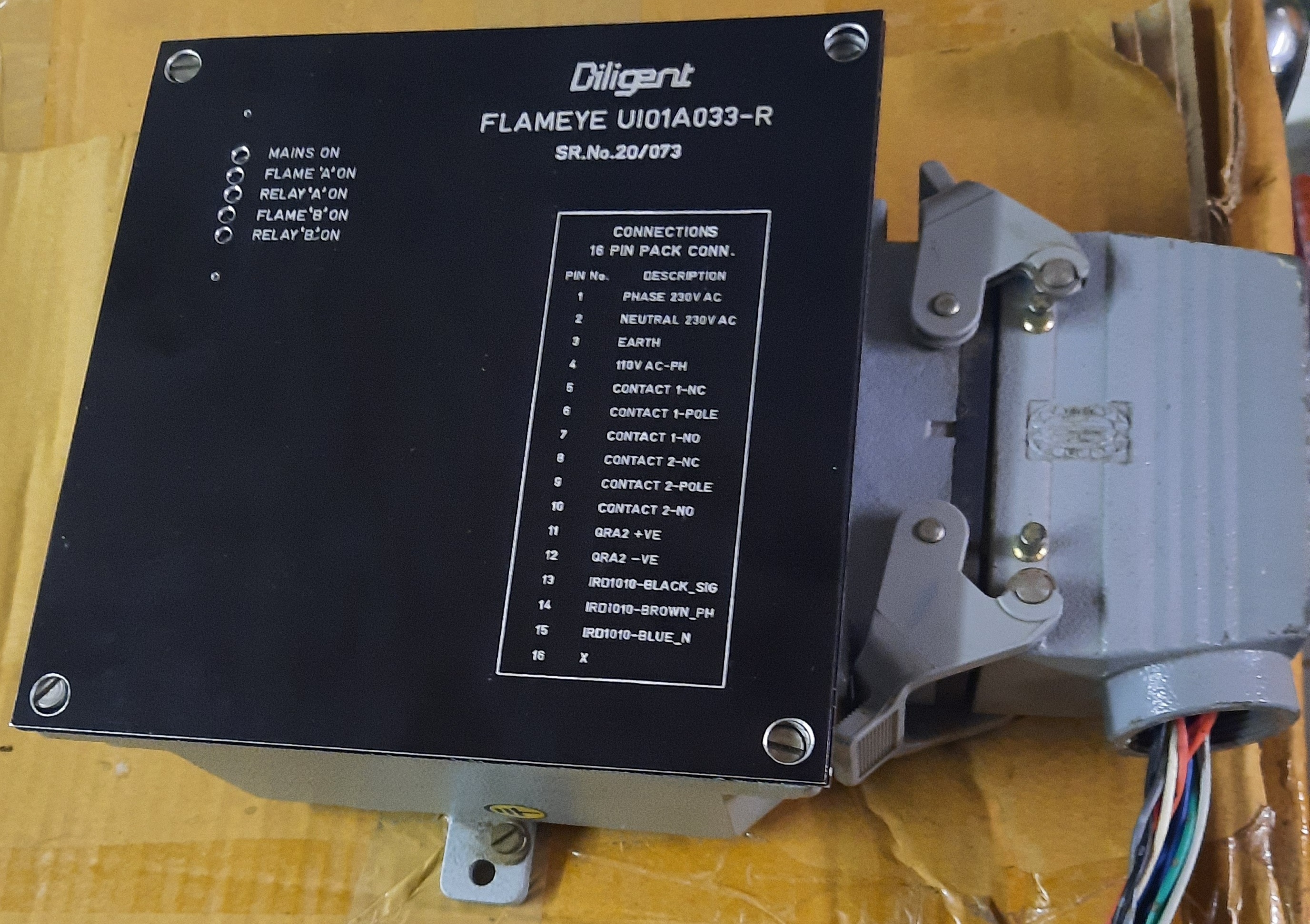

Oil Flame Monitor

4500.0 INR/Piece

Product Details:

- Phase Single Phase

- Material Steel Plate

- Click to View more

X

Oil Flame Monitor Price And Quantity

- 4500.0 INR/Piece

- 1 Piece

Oil Flame Monitor Product Specifications

- Single Phase

- Steel Plate

Oil Flame Monitor Trade Information

- 1 Piece Per Week

- 2 Week

Product Description

Heat has always been very useful to man kind. One of the basic and common ways to obtain heat is by burning combustible fuels. However, such combustion must be controlled and safe. Safety of combustion is ensured by monitoring flame. Flame is characterized by emission of wide spectrum of electromagnetic radiation starting from infra red, visible light to ultra-violet radiations. Flame is also known to generate ions in its envelope. Type of fuel and that of burner decides which one of these radiations predominate. For example; flame of coal or oil is usually very bright and yellow in color, flame of light oil like kerosene or that of hydrocarbon gas is light blue and flames of some gases may be even dull reddish. In addition to this, intensity of flame could differ widely depending on the type and size of flame. Hence different techniques have evolved and new ones are being developed to detect and monitor flames. DILIGENT

DILIGENT MICRO CONTROLS has developed wide range of Oil Flame Monitors "Diligent Flameye".

1. Flameye PR for Oil Flame

Diligent Flameye PR is flame monitor designed to work with Photo Resistor type flame sensor which respond efficiently to the bright yellow light. Such light is emitted by oil flame and, therefore, Diligent Flameye PR is used in most of the oil burners.

2. Flameye PV for Oil Flame

Diligent Flameye PV is flame monitor designed to work with Photo Voltaic type flame sensor which respond efficiently to the bright yellow light by producing active dc milli volt signal. Such light is emitted by oil flame and, therefore, Diligent Flameye PV is used in the oil burners.

3. Flameye IR (Infrared) for Coal, Oil & Gas Flames

Diligent Flameye IR is flame monitor designed to work with Infra Red type flame sensor which respond efficiently to the infra red electromagnetic radiations present in the flame. Infra Red radiations are also given out by hot surface such as hot refractory lining in furnace. However, Diligent Flameye IR effectively detects flame by picking up the fluctuating infra red flux that is present only in flame. It uses infra red sensor type IRD 1010 of Satronics ( now Honeywell) make.

4. Flameye UV (UltraViolet) for Oil & Gas Flame

Diligent Flameye UV is flame monitor designed to work with Ultra Violet type flame sensor which respond efficiently to the ultra violet electromagnetic radiations present in the flame. Ultra violet electromagnetic radiations are given out by all the combustion process. However, Diligent Flameye UV effectively detects flame by picking up the ultra violet flux that is present in the flame. It uses ultra violet sensor type QRA-2 of Landis & Gyr (now Siemens) make. Diligent Flameye UV models are also available for working with other types of UV flame sensors such as C7027 of Honeywell make, UV2 of Fireye make, Kromshrodder make, etc.

5. Flameye N (Ionization) for Gas Flame

Diligent Flameye N is flame monitor designed to detect the flame by picking up ions which are present in the flame. Gas flame, unlike oil flame, is blue and is nearly not detectable by conventional sensors like Photo Resistor or Photo Voltaic sensors. Such flame is easily and effectively detected by picking up ions present in it. The only condition for reliable sensing of flame by this is that the flame must be properly set & stable to ensure unbroken path of ionic current.

6. Dual Flameye UI (UV & IR) / UU (UV & UV)

Diligent Dual Flameye are designed to sense same flame by two independent sensors and flame presence decision is confirmed either by AND or OR logic of two flame. Such flame monitors are vary useful, when the operating ever changing environment renders one technique non operational for some time. These are also useful when two independent burners are fired in common chamber and operation require that both burners be switched off if either of the flame is lost or security fails.

7. Flameye with Flame ON / OFF Delay

Diligent Flameye is also available with fixed or variable delay for Flame ON or Flame OFF response. This is very useful when flame is not steady or inherently obscured by the environmental conditions; such as Flare Tower flame monitoring..

8. Flameye as Import Substitute for most of the popular type

i. Flameye substitute for M/s Landis & Gyr make (now Siemens make) flame amplifiers such as; LAE10, LFE10, etc.

ii. Flameye substitute for M/s Honeywell make flame amplifier type R4343

Advanced Flame Monitoring Technology

Our Oil Flame Monitor incorporates the latest sensory advancements to provide early flame detection and improved operational control. Its natural circulation type ensures efficient functionality, safeguarding against combustion failures and contributing to workplace safety.

Durable and Reliable Construction

Built with high-quality steel plate, this monitor is engineered for longevity and consistent performance in demanding industrial environments. Its single-phase operation integrates smoothly with standard electrical systems, offering adaptability for a broad range of uses.

FAQ's of Oil Flame Monitor:

Q: How does the Oil Flame Monitor work in natural circulation systems?

A: The Oil Flame Monitor detects the presence and quality of the flame within oil-fired natural circulation setups by using sensitive sensors. This ensures that the system operates safely, shutting down automatically if any irregularity or flame failure is observed.Q: What are the primary benefits of using a steel plate Oil Flame Monitor?

A: The steel plate construction offers durability and resistance to environmental wear, providing stable operation and a long service life even in challenging industrial conditions.Q: When should the Oil Flame Monitor be installed or replaced?

A: It should be installed during the setup of any new oil-fired system or replaced when existing monitoring devices show signs of malfunction, such as inaccurate readings or delayed flame detection. Regular inspections help determine the ideal replacement time.Q: Where can this Oil Flame Monitor be used effectively?

A: This monitor is suitable for application in industries with oil-fired boilers or burners that utilize natural circulation mechanisms, such as power plants, manufacturing units, and refineries across India.Q: What is the process for installing the single-phase Oil Flame Monitor?

A: Installation involves connecting the monitor to your oil-fired unit's electrical and combustion system, following manufacturer guidelines. Qualified technicians typically carry out the process to ensure proper setup and calibration.Q: How does using an Oil Flame Monitor enhance safety in industrial operations?

A: By providing continuous surveillance of the flame, the monitor helps avert hazardous situations caused by flame losses or malfunctions, triggering preventive actions and contributing to overall plant safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese