- Home Page

- Company Profile

- Our Products

- Contact Us

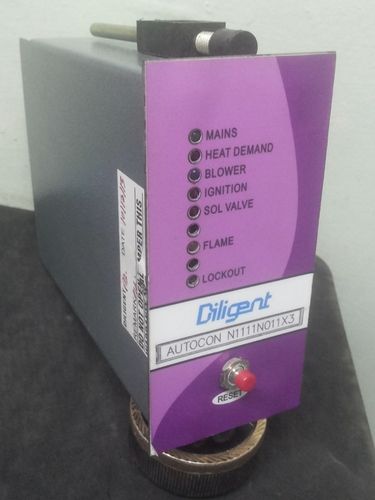

Automatic Oil Burner Controller

3150.00 INR/Piece

Product Details:

- Condition New

- Size Different Available

- Usage Industrial, Power Station

- Weight 200 Grams (g)

- Color Grey And Black

- Material Metal/Plastic

- Click to View more

X

Automatic Oil Burner Controller Price And Quantity

- 1 Piece

- 3150.00 INR/Piece

Automatic Oil Burner Controller Product Specifications

- Different Available

- Industrial, Power Station

- New

- 200 Grams (g)

- Grey And Black

- Metal/Plastic

Automatic Oil Burner Controller Trade Information

- 7 Days

Product Description

Automatic Oil Burner Controller is a compact and sturdy component that is designed for oil-fired heating systems to control combustion of gases that result in efficient and safe operation. This heavy-duty electrical device functions by controlling fuel supply and ignition. The offered controller is provided with a series of connecting ports to rigidly fix electrical wires using mechanical fasteners. Our offered product has a sturdy ABS plastic body that gives high impact strength and fire resistance. The offered product can be delivered to our clients as per their requirements at a reasonable price.

Automatic Oil Burner Controller Specifications:

1. Voltage: 230 V

2. Model Name/Number: Flameye UX00A022

3. IP Rating: IP40

4. Frequency (Hz): 50 - 60

5. Automation Grade: Automatic

6. Power Source: 230V AC

7. Phase: Single

8. Elecrical Load: $ Amp Resistive at 230V AC

9. Serial Number: 05/147

Automatic Oil Burner Controller Applications:

1. Residential Heating Systems: Automatic oil burner controllers are widely used in residential heating systems, such as furnaces, boilers, and water heaters. They regulate the oil burner's ignition, fuel supply, and combustion process to maintain a comfortable indoor temperature while minimizing fuel consumption and emissions.

2. Commercial and Industrial Heating: Many commercial and industrial facilities rely on oil-fired heating systems to maintain appropriate temperatures for processes, equipment, and employee comfort. Automatic oil burner controllers help optimize fuel usage and maintain consistent heating levels in these settings.

3. Hot Water Generation: In buildings like hotels, hospitals, and multifamily residences, automatic oil burner controllers are used to manage the heating of water for domestic use. These controllers ensure that hot water is available on demand while using fuel efficiently.

4. Power Generation: Oil-fired power generators often utilize automatic oil burner controllers to efficiently burn oil and produce steam, which is then used to generate electricity. These controllers help maintain stable and efficient combustion processes, which are crucial for power production.

5. Process Heating: Industries such as food processing, chemical production, and manufacturing often require precise control over heating processes. Automatic oil burner controllers can regulate the temperature and combustion parameters to ensure consistent and reliable heat for various manufacturing stages.

6. Greenhouse Heating: Greenhouses use heating systems to create optimal growing conditions for plants. Automatic oil burner controllers help maintain the required temperature and humidity levels while minimizing energy consumption.

7. Oil-Fired Boilers: Automatic oil burner controllers are commonly used in oil-fired boilers for both residential and industrial applications. These controllers ensure proper combustion and efficient heat transfer, leading to cost savings and reduced environmental impact.

8. Waste Oil Heaters: Some facilities, such as auto repair shops, use waste oil heaters to recycle used oil for heating purposes. Automatic oil burner controllers manage the combustion process, allowing for the safe and efficient use of waste oil.

9. Drying Processes: Industries that involve drying materials, such as wood processing or textile manufacturing, use automatic oil burner controllers to regulate the heat source. This ensures consistent and controlled drying without wasting energy.

10. Remote Monitoring and Control: Many modern automatic oil burner controllers are equipped with remote monitoring and control capabilities. This is particularly useful for facilities with multiple heating systems spread over a large area. Remote access allows for adjustments, troubleshooting, and diagnostics without physically being at the site.

FAQ:

Q. What is an automatic oil burner controller?

Ans: An automatic oil burner controller is an electronic device that regulates the operation of oil burners in heating systems. It controls functions like fuel ignition, combustion, fuel supply, and safety features to ensure efficient and safe heating.

Q. Why do I need an automatic oil burner controller?

Ans: Automatic oil burner controllers optimize fuel combustion, improve energy efficiency, reduce emissions, and enhance overall system reliability. They also provide safety features to prevent hazardous conditions.

Q. How does an automatic oil burner controller work?

Ans: The controller uses sensors to monitor parameters such as temperature, pressure, and flame presence. It processes this information to control the fuel pump, air intake, ignition, and other burner components for optimal combustion.

Q. What are the benefits of using an automatic oil burner controller?

Ans: Benefits include improved fuel efficiency, reduced fuel consumption, lower emissions, consistent heating performance, increased safety through built-in safeguards, and often remote monitoring and control capabilities.

Q. Are these controllers compatible with different types of oil burners?

Ans: Yes, automatic oil burner controllers are designed to work with various types and sizes of oil burners, including residential, commercial, and industrial applications.

Q. Can I retrofit an existing oil burner with an automatic controller?

Ans: In many cases, yes. There are retrofit kits available that allow you to upgrade older oil burners with modern automatic controller technology. However, compatibility and installation requirements should be confirmed.

Q. What safety features do these controllers offer?

Ans: Automatic oil burner controllers usually include safety features like flame monitoring and detection, safety shutdowns in case of malfunction, pressure and temperature limits, and emergency shut-off functions.

Q. Do automatic oil burner controllers require maintenance?

Ans: Yes, like any electronic device, maintenance is important. Regular inspections, cleaning, and calibration are recommended to ensure accurate operation and safety compliance.

Q. Can I control my oil burner remotely with these controllers?

Ans: Many modern controllers offer remote monitoring and control capabilities through smartphone apps or web interfaces, allowing you to make adjustments and receive alerts from a distance.

Q. Are there different modes of operation in these controllers?

Ans: Yes, many controllers offer multiple operating modes, such as automatic, manual, and standby modes. This flexibility allows you to adapt the system to different requirements.

Q. Do these controllers work with other heating system components?

Ans: Yes, they can integrate with other heating system components like thermostats, pumps, valves, and sensors to create a comprehensive and coordinated heating system.

Q. Are there energy savings associated with using automatic oil burner controllers?

Ans: Yes, automatic controllers optimize combustion parameters, leading to improved fuel efficiency and reduced energy consumption, which in turn can lead to cost savings.

Q. Are there any regulatory standards for these controllers?

Ans: Yes, depending on your location and application, there might be regulations or standards that oil burner controllers need to adhere to. Check with local authorities or relevant industry standards.

Q. Can I install an automatic oil burner controller myself?

Ans: Installation might require technical expertise. It's recommended to consult the product manual and, if unsure, seek assistance from a qualified technician to ensure proper installation and safety.

Robust Construction for Industrial Use

Made from high-quality metal and plastic, the Automatic Oil Burner Controller is built to withstand the tough demands of industrial environments. Its compact design and lightweight 200-gram build make it easy to handle and install in various machines, ensuring reliable operation across sectors such as industrial automation, manufacturing, and power generation.

Advanced Automation and Control

Designed to modernize oil burner management, this controller offers precise regulation and safeguards. It streamlines complex processes, improves energy efficiency, and minimizes manual intervention, helping industries achieve safer and more efficient operations. Integration is simple, making it suitable for both new installations and system upgrades.

FAQ's of Automatic Oil Burner Controller:

Q: How is the Automatic Oil Burner Controller used in industrial automation applications?

A: The controller integrates with oil burners and machinery to automatically regulate operations, ensuring consistent performance and safety. It works by monitoring and controlling burner functions, eliminating the need for manual oversight.Q: What materials are used in the construction of the Automatic Oil Burner Controller?

A: This product is manufactured using robust metal and plastic components, offering durability and resistance to industrial conditions while maintaining a lightweight design for easy handling.Q: When should industries consider installing an Automatic Oil Burner Controller?

A: Industries should upgrade to automatic controllers when seeking improved efficiency, enhanced safety, and reduced manual intervention in their oil burner systems, especially during modernization or expansion projects.Q: Where can I purchase the Automatic Oil Burner Controller in India?

A: You can obtain this controller directly from reputable manufacturers, suppliers, or traders located across India, ensuring accessibility for industrial clients countrywide.Q: What is the process for integrating this controller into existing oil burner systems?

A: Integration involves connecting the controller to the oil burner and automation system as per product guidelines. Professional installation is recommended to ensure compatibility and optimal operation.Q: How does using an automatic controller benefit industrial operations?

A: Employing an automatic controller increases operational reliability, reduces errors, and improves energy efficiency. It enhances the safety of oil burner systems while cutting down maintenance costs and downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese