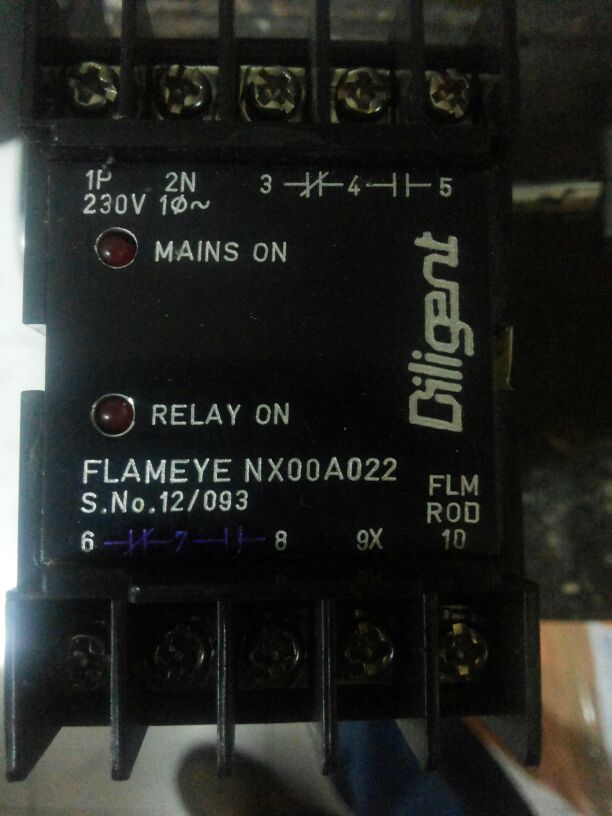

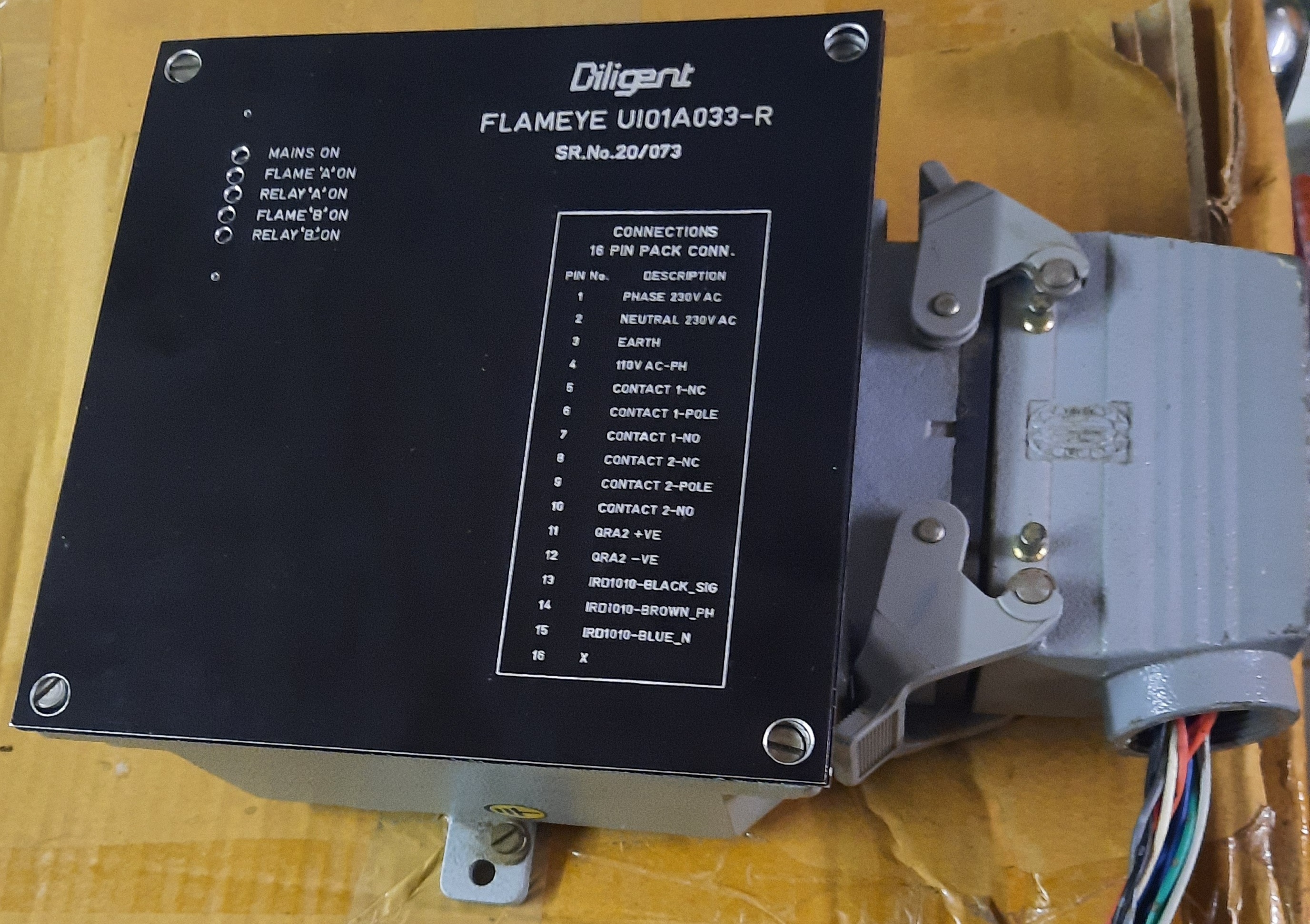

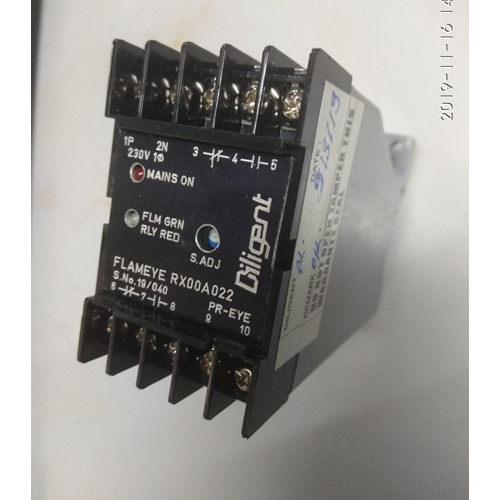

Ionization Flame Monitor

4500.0 आईएनआर/टुकड़ा

उत्पाद विवरण:

- परिचालन तापमान सेल्सियस (oC)

- फेज

- एप्लीकेशन Flame Detection in Industrial Burners and Boilers

- बिजली की आपूर्ति AC Mains

- ठंडा करने की विधि Natural Air Cooled

- विशेषताएँ Reliable ionization flame detection, high sensitivity, LED indicators, compact design, durable construction

- आउटपुट टाइप

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- टुकड़ा/टुकड़े,

- टुकड़ा/टुकड़े

- 1

उत्पाद की विशेषताएं

- Terminal Block

- ग्राम (g)

- सेल्सियस (oC)

- वोल्ट (V)

- 0.9

- सेल्सियस (oC)

- Yes

- AC Mains

- Flame Detection in Industrial Burners and Boilers

- सेल्सियस (oC)

- Ionization Flame Monitor

- Reliable ionization flame detection, high sensitivity, LED indicators, compact design, durable construction

- High

- हर्ट्ज (एचजेड)

- Natural Air Cooled

- Stable

- Plastic

व्यापार सूचना

- प्रति सप्ताह

- हफ़्ता

उत्पाद वर्णन

Ionization Flame Monitor manufactured and supplied by us are highly applauded and demanded for their many positive attributes such as fine quality, durability, smooth finish and more. Processed with high grade raw material and components, these monitor are highly effective in detecting other undetectable gases that can invisible too. Quality tested by the analyzer after production for its accurate functioning, these products are availed by us at affordable reasonable market rates.

Applications of Ionization Flame Monitor:

1. Boilers and Furnaces: IFMs are widely used in boilers and furnaces to ensure the presence of a flame during the combustion process. If the flame goes out unexpectedly, the IFM will detect it and initiate safety measures to prevent hazardous conditions or damage to the equipment.

2. Gas Turbines: Gas turbines are used in power generation and various industrial processes. IFMs play a critical role in these applications by continuously monitoring the flames in combustion chambers to prevent fuel leaks or combustion instability that could damage the turbine or compromise its efficiency.

3. Burners and Incinerators: In industrial burners and waste incinerators, IFMs help to optimize combustion efficiency by ensuring a stable flame. They can detect flame instability or fluctuations, allowing for immediate adjustments to maintain optimal combustion conditions.

4. Process Heaters: Many industrial processes involve the use of process heaters. IFMs are employed in these systems to monitor the flame and prevent situations like incomplete combustion, which can lead to energy waste, emissions, and unsafe conditions.

5. Oil and Gas Industry: IFMs are used in the oil and gas sector for applications like flare stacks and pilot burners. Flare stacks burn off excess gases safely, and IFMs ensure that the flames are present and properly burning to prevent the release of unburned hydrocarbons into the atmosphere.

6. Safety Systems: IFMs are an integral part of safety systems in industries involving combustion processes. In case of flame failure, these monitors can trigger alarms, shut off fuel supplies, and initiate safety protocols to prevent potential hazards.

7. Chemical Processing: Combustion is often used in chemical processes. IFMs assist in maintaining consistent combustion to achieve the desired reaction conditions and to prevent the accumulation of flammable gases or hazardous conditions.

8. Ovens and Kilns: IFMs are utilized in industrial ovens and kilns to monitor the flames that provide the necessary heat for baking, drying, or firing processes. Ensuring a stable flame helps maintain product quality and energy efficiency.

9. Power Plants: In power plants, where combustion processes generate steam to drive turbines, IFMs are crucial for ensuring continuous combustion and preventing equipment damage. They are used in various types of power plants, including coal, gas, and biomass-fired facilities.

10. Environmental Monitoring: IFMs can be used in environmental applications to monitor open flames, such as those in controlled burns used for land management or in research related to fire behavior and emissions.

FAQ:

1. What is an Ionization Flame Monitor (IFM)?

Ans: An Ionization Flame Monitor (IFM) is a device used in combustion systems to detect the presence or absence of a flame. It operates based on the principle of monitoring the ionization zone in a flame. When a flame is present, it produces ions that can conduct electricity. The IFM detects these ions and uses the conductivity changes to determine the flame's status.

2. How does an IFM work?

Ans: An IFM consists of an ionization electrode and a reference electrode placed near the flame. When a flame is present, it ionizes the surrounding gases, creating a conductive path between the ionization electrode and the reference electrode. The IFM measures the conductivity between these electrodes. If the conductivity is above a certain threshold, the IFM registers the presence of a flame.

3. What is the purpose of an Ionization Flame Monitor?

Ans: The primary purpose of an IFM is to ensure the safe and efficient operation of combustion systems. It detects flame failure, unstable flames, or other combustion irregularities. In the event of a flameout, the IFM can trigger safety measures, such as shutting off fuel flow or activating alarms, to prevent hazards and equipment damage.

4. Where are IFMs used?

Ans: IFMs are used in a wide range of industrial applications, including boilers, furnaces, gas turbines, burners, incinerators, process heaters, and more. They are also found in power plants, the oil and gas industry, chemical processing, and environments where open flames are present.

5. What are the benefits of using Ionization Flame Monitor?

Ans: Here are some of the benefits of using this product:

a. Safety: IFMs enhance safety by preventing situations where fuel is being supplied without a flame present, reducing the risk of gas leaks or uncontrolled combustion.

b. Efficiency: By ensuring continuous and stable combustion, IFMs help optimize energy efficiency and reduce emissions.

c. Equipment Protection: IFMs prevent damage to equipment that can result from incomplete combustion or flame instability.

d. Regulatory Compliance: Many industries are subject to safety regulations that require flame monitoring to prevent hazards and emissions.

6. How do IFMs contribute to combustion efficiency?

Ans: Ionization Flame Monitor help maintain a consistent and stable flame, which is essential for efficient combustion. Incomplete or unstable combustion can lead to wasted fuel, increased emissions, and reduced overall system efficiency.

7. Can IFMs work with different types of fuels?

Ans: Yes, IFMs can be designed to work with various types of fuels, including natural gas, oil, coal, biomass, and more. The specific design may need adjustments based on the characteristics of the fuel being used.

8. How reliable are Ionization Flame Monitor?

Ans: IFMs are generally reliable and widely used in industrial settings. However, like any technology, they require proper installation, calibration, and maintenance to ensure accurate and consistent performance.

9. What happens if an IFM detects a flame failure?

Ans: If an IFM detects a flame failure, it can trigger various safety actions. These actions might include shutting off the fuel supply, activating alarms to alert operators, or initiating protocols to prevent hazards.

10. Can Ionization Flame Monitor be integrated into control systems?

Ans: Yes, IFMs can be integrated into the control systems of combustion equipment. This integration allows for automated responses to flame failure or instability, enhancing the safety and efficiency of the system.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese