Dual Flame Monitor

उत्पाद विवरण:

- शोर का स्तर डीबी

- परिचालन तापमान सेल्सियस (oC)

- प्रॉडक्ट टाइप Dual Flame Monitor

- इनपुट वोल्टेज वोल्ट (V)

- वोल्टेज सुरक्षा YES

- दक्षता 98-99%

- उपयोग/अनुप्रयोग used in various industrial applications to detect and monitor the presence and quality of flames in combustion processes

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Single / Three

- YES

- हर्ट्ज (एचजेड)

- 98-99%

- Dual Flame Monitor

- डीबी

- वोल्ट (V)

- सेल्सियस (oC)

- used in various industrial applications to detect and monitor the presence and quality of flames in combustion processes

व्यापार सूचना

- दिन

उत्पाद वर्णन

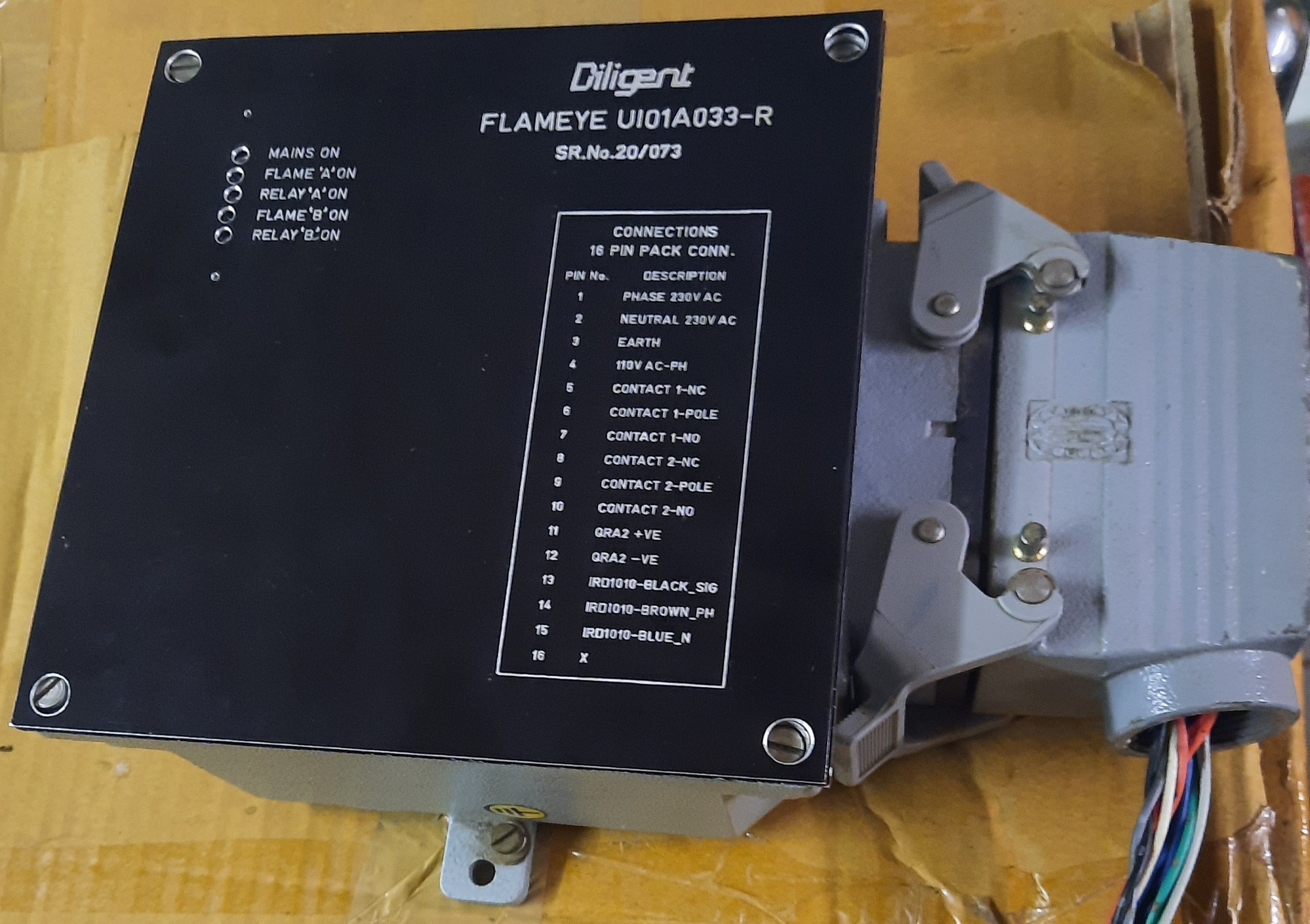

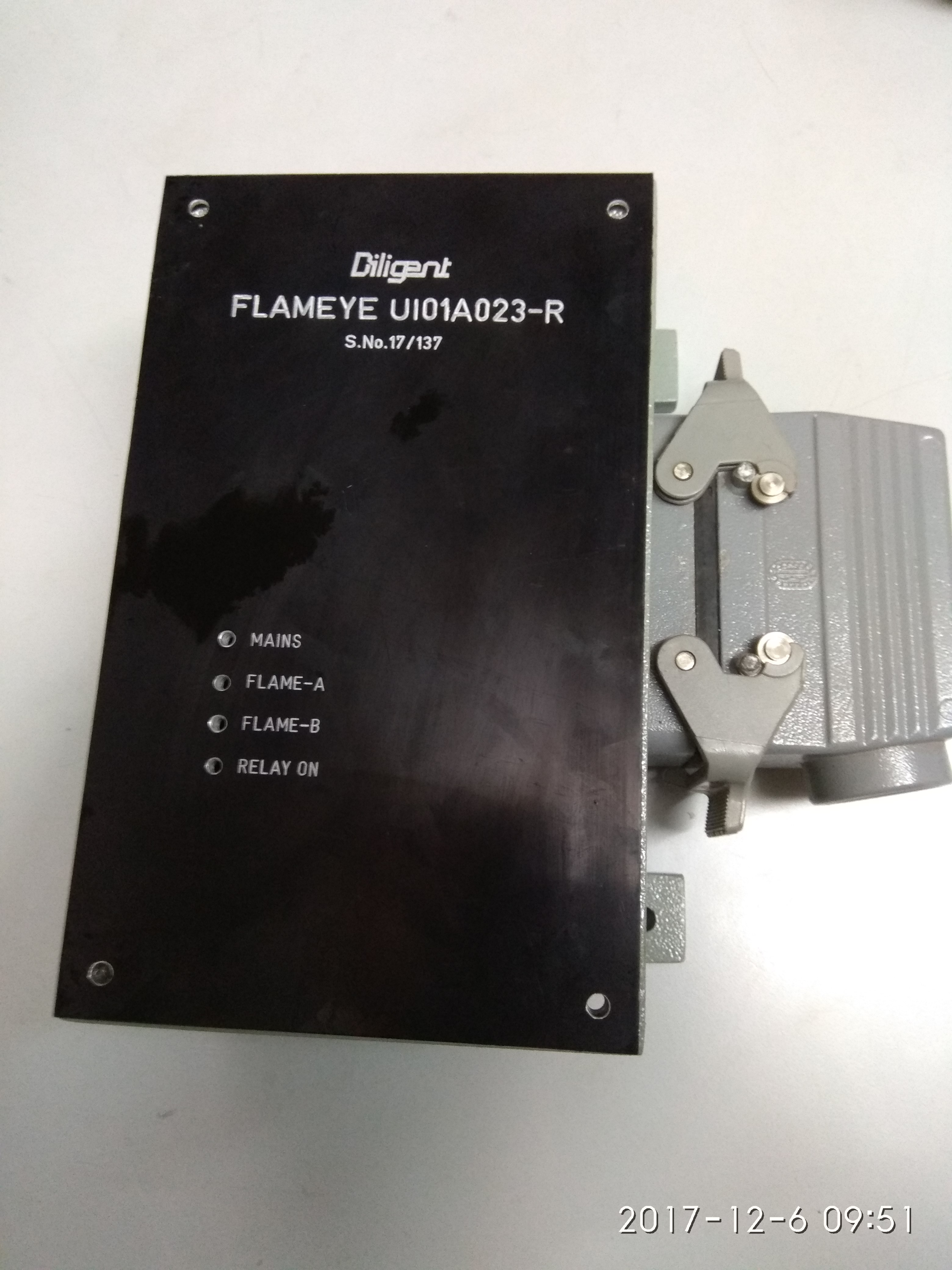

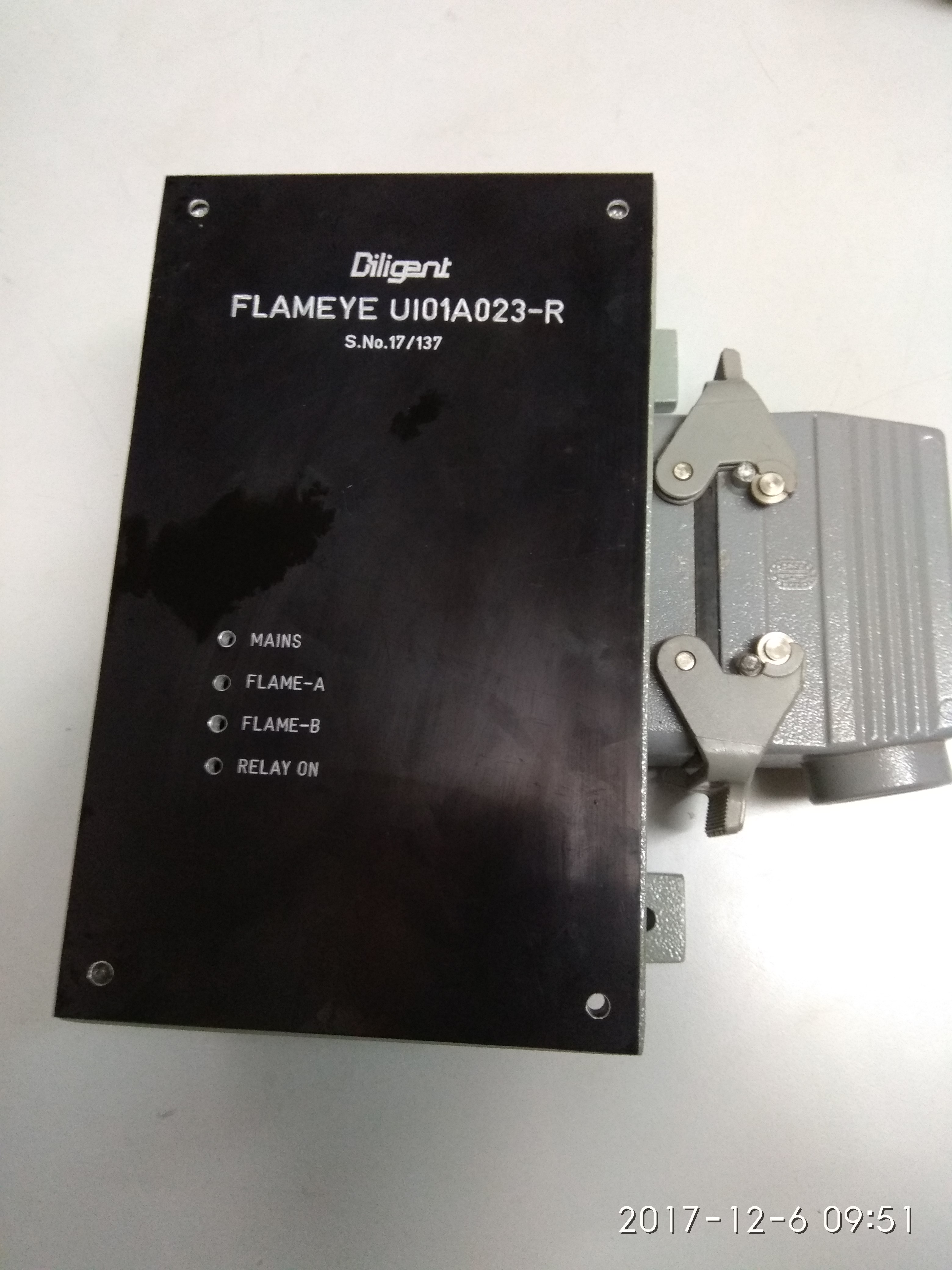

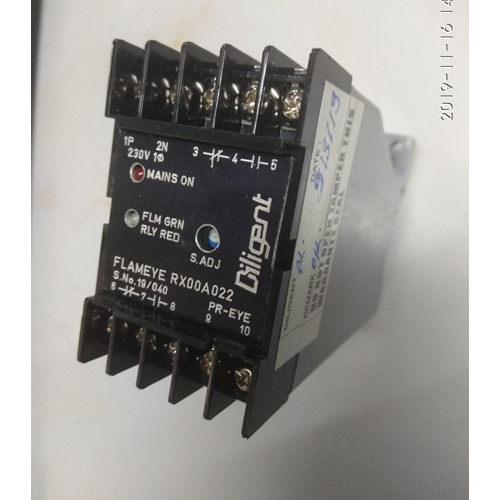

Dual flame monitor is a flame monitoring system that has two separate flame sensors or monitoring channels. This redundancy can provide increased safety and reliability. If one sensor or channel fails, the other can still detect the flame and trigger appropriate actions, such as shutting down the system or alerting operators.

This device is used in various industrial applications to detect and monitor the presence and quality of flames in combustion processes, such as those found in boilers, furnaces, and other heating equipment. It ensures the safe and efficient operation of these processes by detecting any flame failures, ignition problems, or other issues that could lead to unsafe conditions or reduced efficiency.

FAQ:

Q1: What is a Dual Flame Monitor?

Ans: A Dual Flame Monitor is a safety device used in industrial combustion processes to detect and monitor the presence and quality of flames. It incorporates two separate flame monitoring channels for redundancy and increased reliability.

Q2: Why is redundancy important in flame monitoring?

Ans: Redundancy ensures that if one flame monitoring channel fails due to sensor malfunction or other issues, the other channel can still detect and monitor the flame. This enhances safety and minimizes the risk of undetected flame failures.

Q3: What types of industrial applications use Dual Flame Monitors?

Ans: Dual Flame Monitors are commonly used in applications such as boilers, furnaces, industrial ovens, and other combustion-based processes where maintaining a stable and reliable flame is crucial for safety and efficiency.

Q4: How does a Dual Flame Monitor work?

Ans: A Dual Flame Monitor typically uses specialized sensors to detect the presence of a flame. Each channel in the monitor employs its own set of sensors and signal processing circuitry to monitor the flame's characteristics, such as light intensity or UV radiation. If either channel detects a flame anomaly or failure, it triggers an alarm or safety shutdown.

Q5: What happens if one channel of the Dual Flame Monitor fails?

Ans: If one channel of the Dual Flame Monitor fails, the other channel continues to monitor the flame. However, it's essential to conduct regular maintenance and testing to ensure both channels are functioning correctly.

Q6: How is a Dual Flame Monitor different from a single-channel monitor?

Ans: A single-channel flame monitor has only one set of sensors and monitoring circuitry. If this single channel fails, there is no backup. A dual flame monitor provides an extra layer of safety by incorporating two independent channels.

Q7: Are there specific industry standards for Dual Flame Monitors?

Ans: Yes, different industries might have specific standards and regulations for flame monitoring systems. Examples include NFPA 85 for boilers and furnaces or IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems.

Q8: Can Dual Flame Monitors be integrated into automation systems?

Ans: Yes, Dual Flame Monitors can often be integrated into larger industrial automation systems. They can communicate with control systems to trigger alarms, initiate safety shutdowns, or send alerts to operators.

Q9: How often should a Dual Flame Monitor be tested and maintained?

Ans: Regular maintenance and testing are crucial. Dual Flame Monitors should be inspected according to the manufacturer's recommendations and industry standards. This may involve cleaning sensors, calibrating equipment, and verifying proper functionality.

Q10: Can a Dual Flame Monitor improve operational efficiency?

Ans: Yes, by ensuring reliable and uninterrupted combustion, a Dual Flame Monitor can contribute to operational efficiency by preventing flame failures, reducing downtime, and optimizing combustion processes.

High Efficiency Performance

Achieving an impressive 98-99% efficiency, the Dual Flame Monitor ensures consistent and accurate flame analysis in industrial combustion processes. This high rate of efficiency helps optimize fuel usage and improves overall process reliability, reducing unnecessary downtime and increasing productivity.

Versatile Installation Options

Supporting both single and three-phase electrical configurations and operating safely within input voltages from 100 to 415 V, the Dual Flame Monitor is adaptable for use across various industrial setups. Its broad operating temperature capacity ensures dependable performance in diverse environmental conditions.

Built-in Safety and Warranty

Equipped with advanced voltage protection and a warranty, the Dual Flame Monitor delivers peace of mind for operators concerned about equipment longevity and safety. The integrated protection mechanisms help guard against power fluctuations, further enhancing reliability in demanding operations.

FAQ's of Dual Flame Monitor:

Q: How does the Dual Flame Monitor contribute to combustion process efficiency?

A: The Dual Flame Monitor optimizes combustion processes by accurately detecting and monitoring flame presence and quality, helping ensure consistent burning. Its 98-99% efficiency helps reduce fuel waste and supports stable operations, minimizing maintenance requirements.Q: What industrial applications can benefit from using this monitor?

A: This product is designed for a wide range of industrial applications, including furnaces, boilers, and incinerators, where accurate flame detection and monitoring are essential for safety, process optimization, and regulatory compliance.Q: When should the Dual Flame Monitor be installed in an industrial process?

A: The monitor should be integrated during the installation or upgrade of any combustion system that requires precise flame detection. Installing it at the commissioning phase ensures safety and improves process control from the start.Q: Where can I purchase the Dual Flame Monitor in India?

A: The Dual Flame Monitor is available through authorized manufacturers, suppliers, and traders across India. For warranty and technical support, it is recommended to purchase directly from recognized sources.Q: What steps are involved in setting up the Dual Flame Monitor?

A: Installation involves connecting the monitor to the combustion system, ensuring correct voltage (100-415 V) input, and configuring it for single or three-phase operation as required. Calibration may be needed for optimal accuracy and efficiency.Q: Is there any noise concern associated with the monitor during operation?

A: No, the device has a very low noise output (measured in decibels), making it ideal for environments where minimizing operational sound is critical.Q: What are the main benefits of using a monitor with built-in voltage protection?

A: Integrated voltage protection shields the device against power surges and fluctuations, prolongs the monitor's life, enhances operational safety, and ensures the reliability of flame detection results.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese